The remanufacturing process: Injectors

Our high-quality diesel Turbochargers follow a rigorous remanufacturing process to ensure every part is examined, cleaned, tested and restored to meet OEM specifications.

Our REMAN diesel products combine the quality of a new injector with the competitiveness of a remanufactured system. The products are produced and tested in line with DTIS stringent quality standards. DTIS REMAN Injectors are the smart choice for quality and cost conscious customers.

The following steps describe the measures DTIS takes to remanufacture injectors, creating a product comparable to a new injector.

STEP 1: CORE ACCEPTANCE

Learn how you can benefit from buying one of our many premium remanufactured injectors. You can get a genuine diesel injector, with quality that rivals that of a new one, for a fraction of the price! Trade-in your worn-out injectors and become part of the DTIS family.

The first step in the rebuilding process is a full inspection. If any of the major components are found to be damaged at this point, we will contact you and give you a full quote for repairing or replacing the parts.

STEP 2: DISASSEMBLY

Our INJECTORS and their parts are completely disassembled to prepare every component for inspection, cleaning and when it is needed for restoration.

We carefully disassembled our diesel injectors in all the different parts for the next step.

When it comes to remanufacturing diesel injectors, our very experienced technicians follow standard quality processes to ensure the highest quality of our injectors!

STEP 3: CLEANING

Diesel injectors will always go through extreme environments, that’s why once we disassembled the injector, the different parts and components are cleaned through an exhaustive cleaning process to remove any dirt.

We use high-quality OEM standard processes for cleaning, disassembling and reassembling INJECTORS!

STEP 4: INSPECTION & RESTORATION

At this stage every part of the injector goes through an exhaustive process in which we inspect very carefully and restore when it’s needed, before reassembly, to ensure the highest quality for your diesel engine!

We use a variety of techniques and equipment to ensure every part that goes into a injector meets OEM specifications.

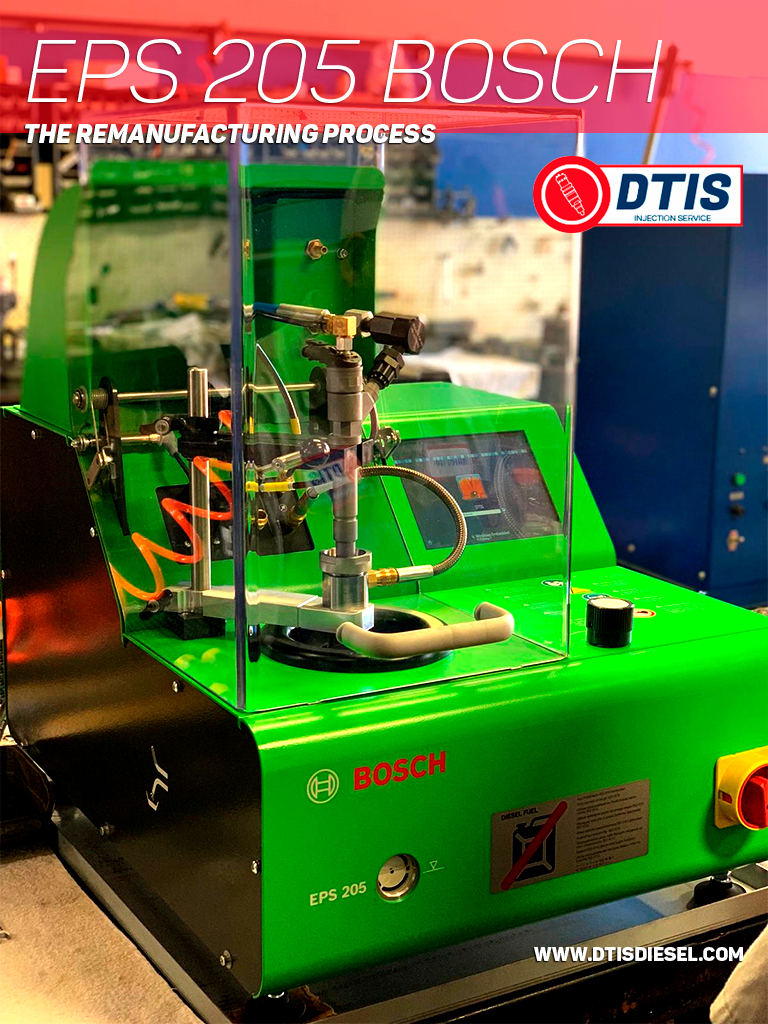

ESP 205 BOSCH

We use a variety of equipment to ensure every part that goes into an injector meets OEM specifications.

ESP 205 BOSCH can test both conventional injection nozzles and common-rail injectors. It can test injectors with an injection pressure of more than 1800 bar and it’s all ours!

Hartridge Toledo HEUI MASTER

We use a variety of equipment to ensure every part that goes into an injector meets OEM specifications.

Hartridge Toledo HEUI MASTER measures the Full Event Response Time (FERT), which give us a complete view of the response time of the injector from electrical activation to the injection event.

STEP 5: REASSEMBLY

Every injector is assembled in a clean environment, following OEM specifications.

At this step we are almost finishing and preparing the remanufactured injector for the last stage.

STEP 6: READY FOR SELL!

Once the remanufacturing process is complete, our Reman Injectors are ready to be introduced to the field, where the true test of quality will be performed.

At this final stage you’ll be able to try them out in your diesel engine!