The remanufacturing process: Turbos

Our high-quality diesel Turbochargers follow a rigorous remanufacturing process to ensure every part is examined, cleaned, tested and restored to meet OEM specifications. Our REMAN diesel products combine the quality of a new turbocharger with the competitiveness of a remanufactured system. They are produced and tested in line with DTIS stringent quality standards.

DTIS REMAN Turbochargers are the smart choice for quality and cost conscious customers. The following steps describe the measures DTIS takes to remanufacture Turbochargers, creating a product comparable to a New Turbocharger.

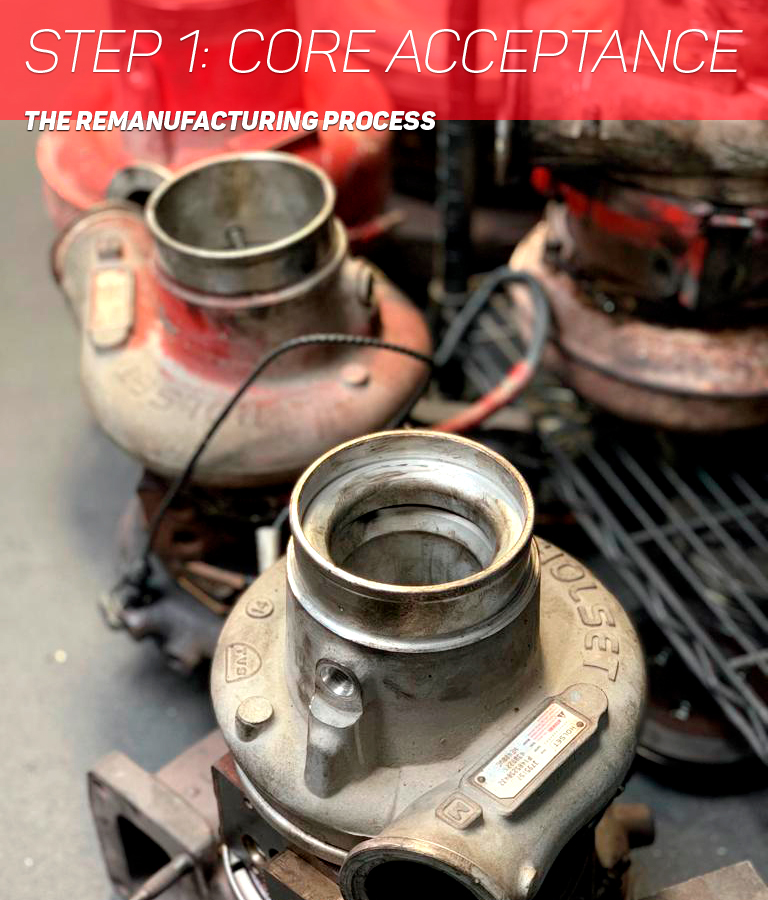

STEP 1: CORE ACCEPTANCE

Learn how you can benefit from buying one of our many premium remanufactured turbochargers. You can get a genuine diesel turbocharger, with quality that rivals that of a new one, for a fraction of the price! Trade-in your worn-out turbochargers and become part of the DTIS family.

The first step in the rebuilding process is a full inspection. If any of the major components are found to be damaged at this point, we will contact you and give you a full quote for repairing or replacing the parts.

STEP 2: MARKING PROCESS

Prior to turbo disassembly, we make sure to use a marking process, that will help us to check the different orientations in the turbocharger. We make sure to use some sort of markings to index the position of each end housing relative to the oil inlet.

Turbochargers will have many different orientations depending upon what engine they are set up for.

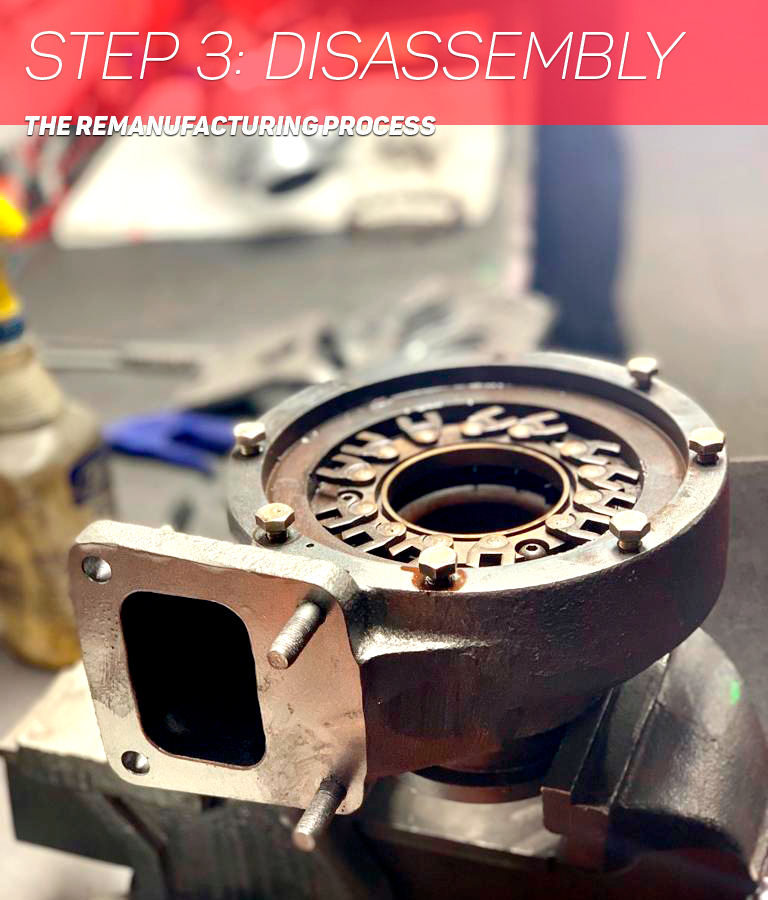

STEP 3: DISASSEMBLY

Our TURBOCHARGERS and their parts are completely disassembled to prepare every component for inspection, cleaning and when it is needed for restoration.

We carefully disassembled our turbochargers in all the different parts for the next step.

When it comes to remanufacturing turbochargers, our very experienced technicians follow standard quality processes to ensure the highest quality of our turbos!

STEP 4: CLEANING

Turbochargers will always go through extreme environments, that’s why once we disassembled the turbo, the different parts and components are cleaned through an exhaustive cleaning process to remove any dirt.

We use high-quality OEM standard processes for cleaning, disassembling and reassembling TURBOCHARGERS!

STEP 5: INSPECTION & RESTORATION

At this stage every part of the turbocharger goes through an exhaustive process in which we inspect very carefully and restore when it’s needed, before reassembly, to ensure the highest quality for your diesel engine!

We use a variety of techniques and equipment to ensure every part that goes into a turbocharger meets OEM specifications.

STEP 6: BALANCING

Balancing is a critical process when rebuilding a Turbocharger, because is absolutely vital to turbo rebuilding, it provides the stability that is critical at high speeds.

Our balancing process exceeds OEM market specifications.

WCB-30

The design of every TURBOCHARGER has a specific ACCURACY of BALANCING in each rotor assembly. Therefore, these must be inspected and balanced to confirm the ROLLING TOLERANCE.

The Model WCB-30 allows to determine the quantity and location of the imbalance, as well as to make the proper corrections and to develop in a precise way the balancing of each rotor assembly for its assembly.

STEP 7: REASSEMBLY

Every turbocharger is assembled in a clean environment, following OEM specifications.

At this step we are almost finishing and preparing the remanufactured turbocharger for the last stage.